development makes

us unique and moves

us forward

Our R&D department has top technologies for research, development and production of prototype samples, including their testing.

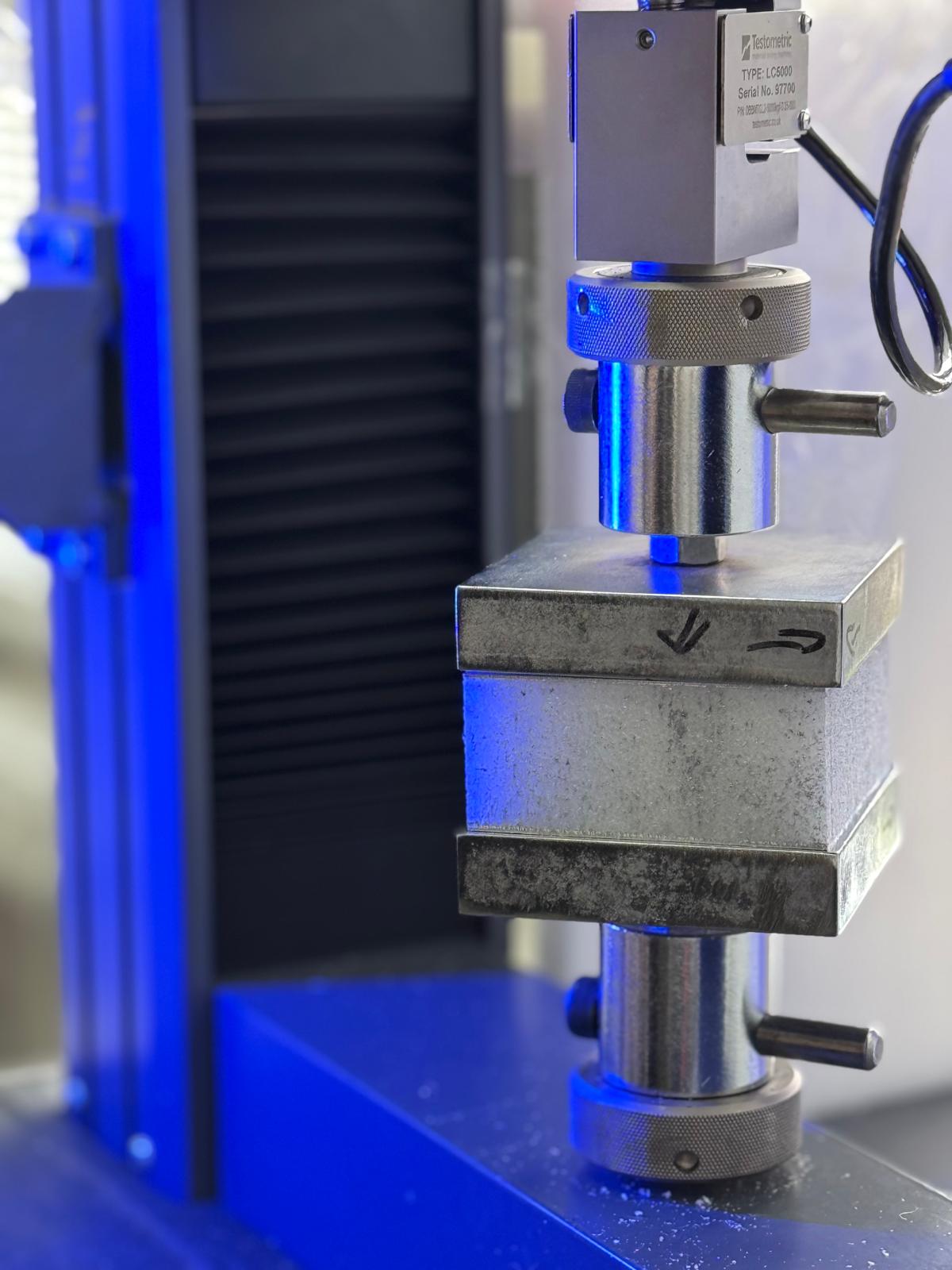

Universal testing machine TESTOMETRIC X500-50 + optical extensometer Xsight ONE

Testing the mechanical properties of the material in tension, compression, 3-point bending, shear, cohesion of layers – peel test, pullout and resistance of screw joints, determination of bearing capacity of fasteners. Machine load range 10 kN, 50 kN.

Differential Scanning Calorimeter Polyma 214 NETZSCH

Thermal analysis of materials in the temperature range 0 to 350 °C in an inert atmosphere of oxygen O2 or nitrogen N2, general methodologies include DSC (according to ISO11357-1), OIT (according to ISO11357-6).

Thermo Scientific Nicolet iS10 FTIR Spectrometer

Qualitative material analysis in ATR mode using a germanium crystal or transmittance mode.

X-ray fluorescence analyzer (XRF) XDelta Olympus

Non-destructive elemental analysis of polymers and composite materials, with a monitoring range of 20 elements.

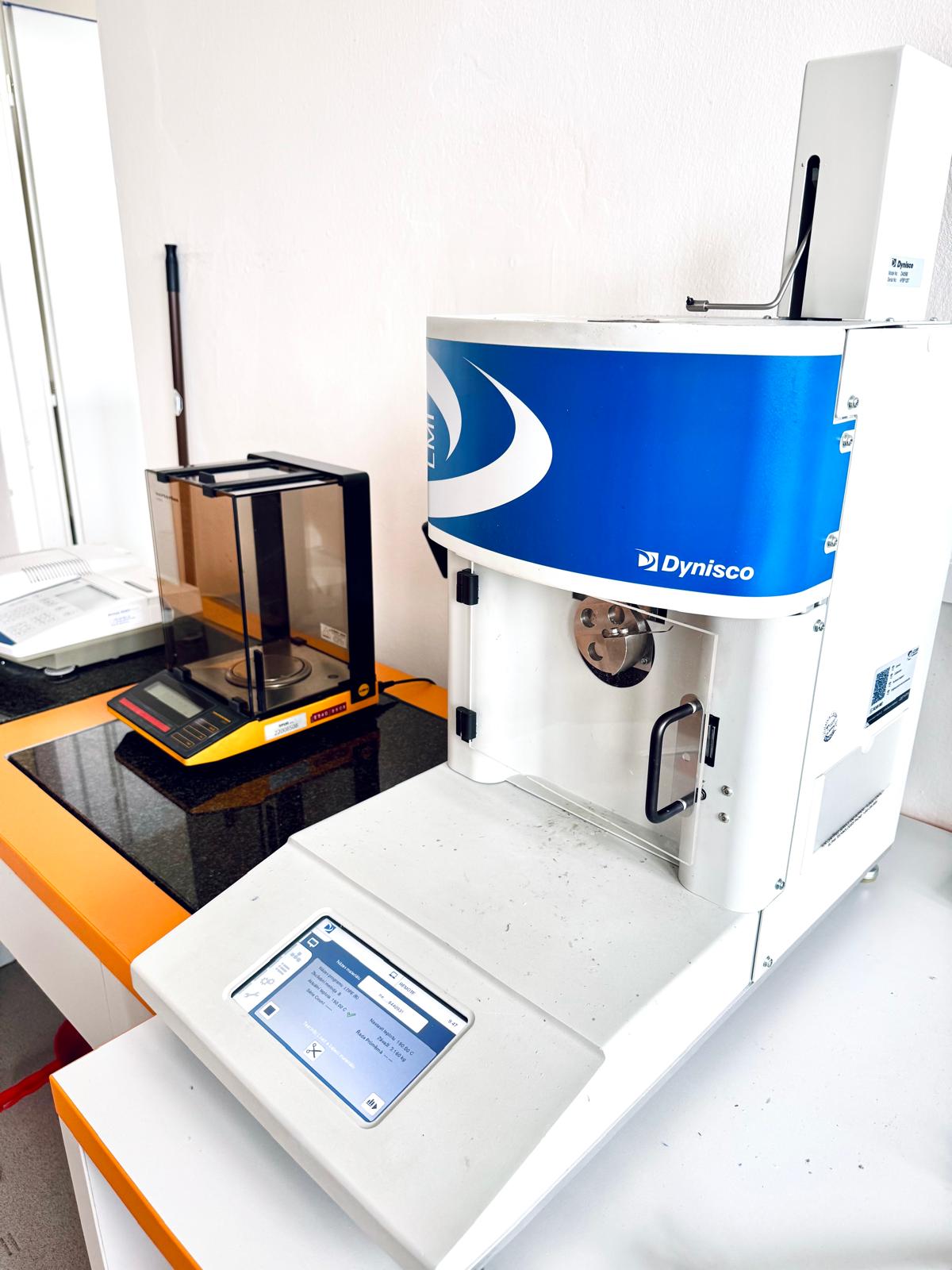

Dynisco LMI 5500 Capillary Plastometer

Basic test of flow and rheological properties of materials (volume and mass flow) in the temperature range up to 400 °C, according to ISO 1133.

BYK SPECTRO 2 GO spectrometer

Determination of yellowness index, whiteness, color deviations from reference values of the material according to the CIELAB chromaticity diagram.

Scanning Electron Microscope Tescan VEGA 3

SEM material image analysis using secondary and backscattered beams, up to a possible magnification range of 20 kx.

QUV Tester (Q-Panel, 340, 313 nm)

Testing of accelerated aging of materials under controlled conditions in UVa, UVb environments according to EN 4892-3.

Laboratory extruder VL240

Processing materials with a melting point of 170-180 °C, commonly PP, PE, PS. Allows dosing of up to 6 components, on a parallel twin-screw, where granules, powder materials, flakes can be processed. Production of string, round, plate profiles. Line mass output 5-50 kg/hour.